Our services

minglecontrol is here for you when you want to optimise processes. This process technology software ensures that your processes are smooth and automated. minglecontrol especially supports you with the following services:

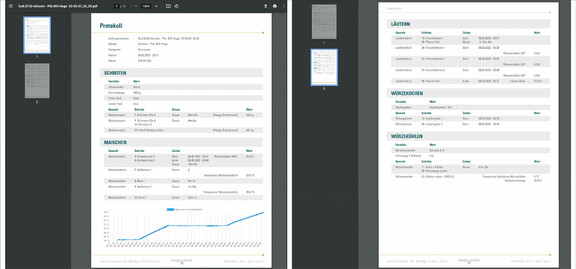

Automated logging of all quality assurance processes

Tedious logging of quality-relevant target and actual data is a thing of the past with minglecontrol. The system captures all data and statuses relevant to the process and documents them long-term. Through a comprehensive long-term data archive, you can access important key figures at any time. This not only makes future decision-making easier, but is also essential for quality assurance. You can individually define which parameters are truly important to you. Accordingly, you receive a customised report which is easy to comprehend thanks to thoughtful visual preparation. For example, graphs give you a good overview of temperature profiles. The report is digitally available, indelible and can be downloaded and locally saved or printed at any time.

Optimised process flows to reduce waiting times

With minglecontrol, you can make your processes more efficient. To ensure an optimised process flow, you have the option to define various starting conditions that kick off production. These include, for example, the condition or production status of other units, or a start after a set time. An important part of this optimisation is also the batch management, which becomes child's play with minglecontrol.

Sophisticated batch management

To reduce waiting times and thus efficiently optimise machine utilisation, processes can be automated with minglecontrol. There are various options*:

- manual start

- Start by time

- Start following a preceding order or status of the unit

Automated batch management is essential to get the most out of your production. The best part: After entering the desired start parameters, no further settings need to be made in the recipe and you do not need to display it separately. However, there is the option to do so. Automatic batch management brings clear advantages:

- More efficient production with maximum machine utilisation

- Time-saving

- The possibility for any employee to start production (provided they have the appropriate user permissions)

- Starting the recipe requires no special qualifications, yet the quality of the product remains constant

Trouble-free user management*

To keep track of changes, orders and processes, minglecontrol offers the option to create users. These users can then be tailored to your employees. User management varies depending on the chosen minglecontrol package. Therefore, a distinction must be made between general users and personalised users. While the former relies on predefined rights, the latter can be assigned individual usage rights. This may include editing recipes or managing orders. This not only reduces susceptibility to errors, but also exclusively gives individual users the app view that specifically concerns them. Irrelevant information is thus directly hidden, and your employees can fully concentrate on their areas of responsibility.

Smooth exchange with ERP and EWM systems*

Do you use an ERP system in your company? No problem! SAP, Oracle, Sage, etc. can be easily coupled with minglecontrol. This not only helps capture important process data but also serves the tracking and logging of batches. The integration of your ERP interface thus enables a more productive approach and facilitates more efficient business processes.

The connection of process technology to an existing EWM system is also no problem, allowing you to track raw materials clearly and easily. This helps you monitor the actual consumed quantities and provides insightful information on the production and value chain, thereby giving you the perfect overview of all inventory levels.

*The specific services included in minglecontrol depend on your selected package. You can find more detailed information here.