PATHUM THANI BREWERY CO. LTD.

Thailand

Installation and automation of a new CIP system in Thailand

Pathum Thani Brewery Co. Ltd.

Founded in 1992, Pathum Thani Brewery is part of Boon Rawd Brewery Co. Ltd., which has been in operation since 1933. In addition to beer, the company also produces various soft drinks and bottled drinking water. The conglomerate's best-known brands include the pale lager Singha and Asahi brand beers, which are exported worldwide.

The parent company, Boon Rawd Brewery Co. Ltd., was Thailand's first brewery and has relied on German expertise for years. Not only were the brewers trained in Germany, but the technology also relied exclusively on German quality products. As a result, Boon Rawd Brewery Co. Ltd. has also acquired breweries in Germany, such as Hartmannsdorf, in addition to the breweries it owns in the Asian market. Boon Rawd Brewery Co. Ltd. has also invested in the German beverage manufacturer Valensia, holding a 49% stake in the company.

600

employes

36,000

bottles of beer per hour

78

tanks

Project description

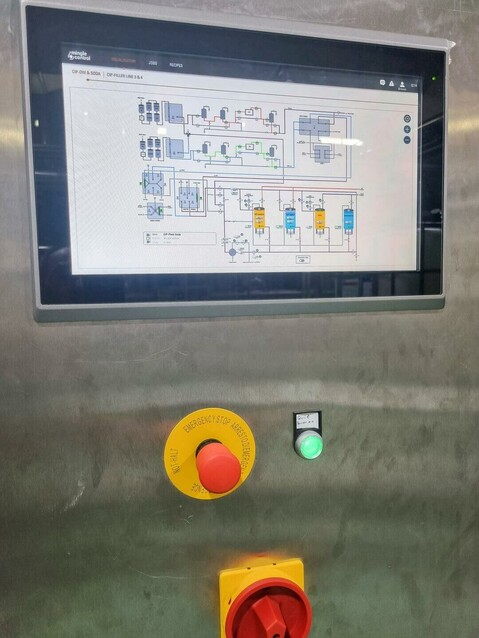

Unlike previous minglecontrol projects, our process control system was now being used in the mineral water and soft drinks sector. Together with our partner LP Project Service GmbH, a new CIP system for cleaning pipelines, filters and soda and drinking water fillers was installed. The aim was to automate its integration into the production process to save time and costs in the future.

For optimal operation of the CIP system, a powerful S71500 CPU, a VPN router and the minglecontrol server were installed in the main control cabinet. A 15.6" touch monitor was also installed in the control cabinet to ensure the best possible on-site access to the system. The permanently installed monitors are perfectly complemented by the remote capability of the minglecontrol process control software.

To make the system's operation understandable to all employees, the software was also designed to be multilingual. Thus, the software can be used by operators on-site and by customer service in Germany in their preferred language.

Special features of the project

Besides making the software multilingual, another challenge was to monitor the 44 manual flaps and 18 spigot arches installed in the pipeline routes according to the selected cleaning path and recipe. Furthermore, it was essential to visually display the necessary manual interventions to the operator before starting.

Through specially developed display objects and the Modal unit, where all subsequent switching conditions are quickly accessible to the user, operators can now easily check their cleaning path (positions of manual flaps, spigot arches, etc.) before starting the cleaning process and ensure that the desired pipeline path has been appropriately set.

Would you like to know what else sets minglecontrol apart? We provide you with numerous reasons why it is exactly the right process technology for your production!