Landskron BRAUMANUFAKTUR

Goerlitz, Germany

Full automation of the CIP cleaning system at Landskron BRAUMANUFAKTUR

Landskron BRAU-MANUFAKTUR GÖRLITZ Dr. Lohbeck GmbH & Co. KG

Two world wars and 40 years of East Germany – with over 150 years in existence, the Landskron BRAU-MANUFAKTUR in Görlitz can look back on a long and intense history. However, this hasn't stopped the brewery. While it used to produce 27,000 hectolitres, today it produces 162,000 hl.

To manage these quantities and meet current technical standards, Landskron replaced the old S5 controller of the CIP plant with minglecontrol and an S7-1500 controller in November 2022. As part of the renewal, the brewery's CIP plant was also equipped with new measuring technology by LP Project GmbH from Nördlingen, bringing it up to the latest state of the art.

<

13

types of beer

160,000

hl brewhouse

Project description

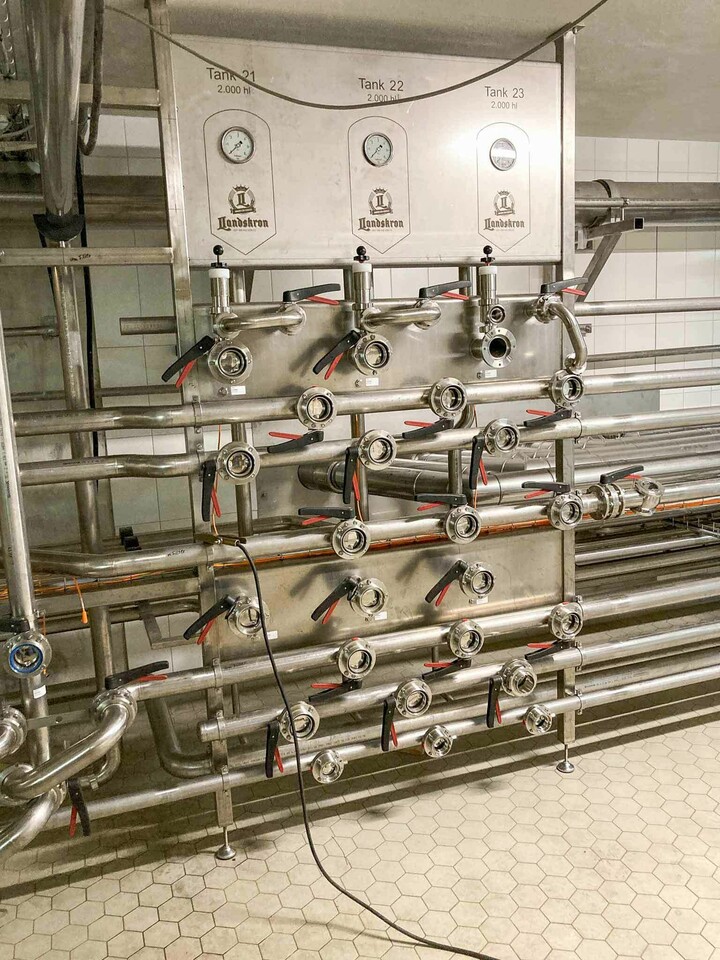

In cooperation with LP Project, the goal was to automate the existing CIP plant and pressure tanks. This step allows the operator to clean its production facilities, vessels, tanks, heat exchangers or pipelines fully automatically. This in turn means that the production facility is cleaned more efficiently, economically and ecologically through fully automated cleaning processes.

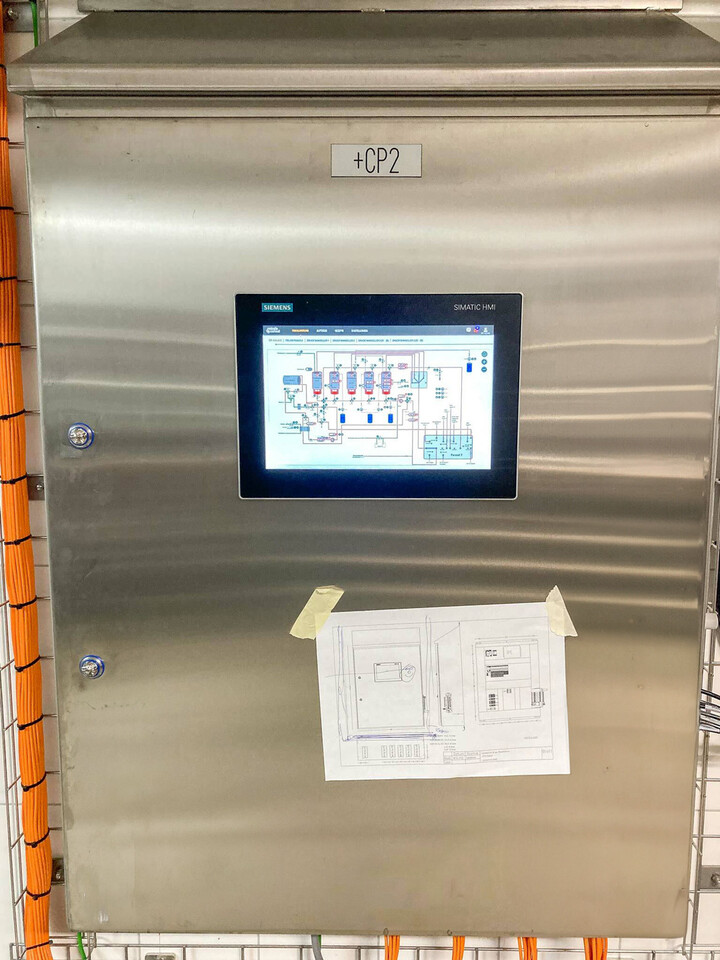

To optimally operate the CIP plant, a CPU, a VPN router and the minglecontrol server were installed in the main control cabinet. In addition to the possibility of remote control via mobile devices, this was supplemented by several permanently installed touch monitors. minglecontrol can then be operated via a 22" touch display directly at the CIP plant, as well as a 12" touch monitor in the cellar. Moreover, operators from their control room, the brewmasters and the maintenance personnel (electricians) can access minglecontrol via their existing PC workstations.

Special features of the project

A particular challenge was the incomplete documentation of the interface to the existing bottle filler. This initially made it difficult to provide the necessary data exchange for its cleaning. However, by analysing the previous S5 software during the planning of minglecontrol, the cleaning and sterile operation of the bottle filler could resume without any problems or delays.

Another special feature was the expansion with nine additional new external pressure tanks with a capacity of 500 to 1,000 hl. All old and new areas of the pressure tank cellar are thus integrated into the PLS system, giving the employees of Landskron BRAU-MANUFAKTUR a full overview of all units and processes.

Would you like to know what else sets minglecontrol apart? We provide you with numerous reasons why it is exactly the right process technology for your production!