OTTENBRAEU

Abendsberg, Germany

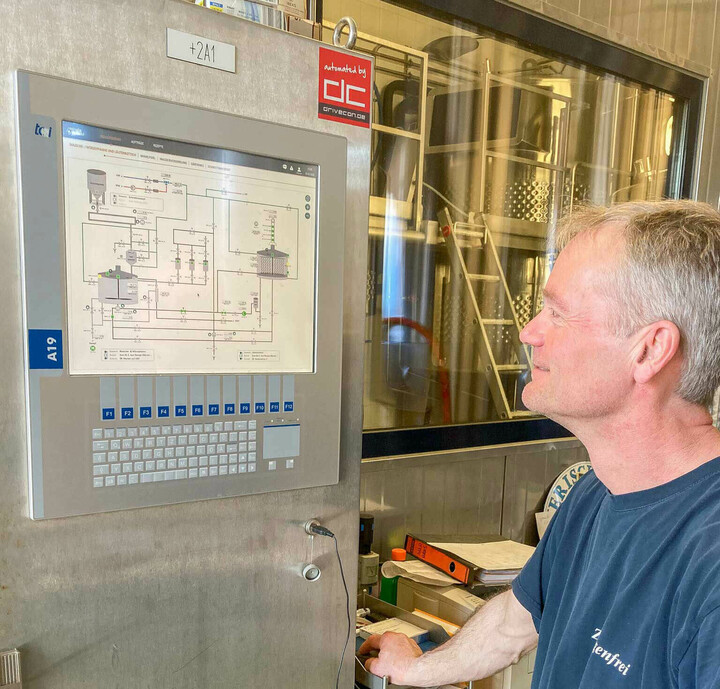

Cross-unit process automation of a one-man operation

Ottenbräu Brewery

A brewery with a long tradition, Ottenbräu was first documented in 1609. The storage cellars are no less historic, with the oldest dating back to the 13th century. In 1846, the brewery came into the possession of the Neumaier family and is now, almost 200 years later, run by Robert Neumaier.

Ottenbräu is a one-man operation, so maximum efficiency is essential. To extract the most from the brewing operation despite minimal staff, Robert Neumaier has relied on the latest technology and automated processes for years.

9

types of beer

20

hl brewhouse

3

brewhouse devices

Project description

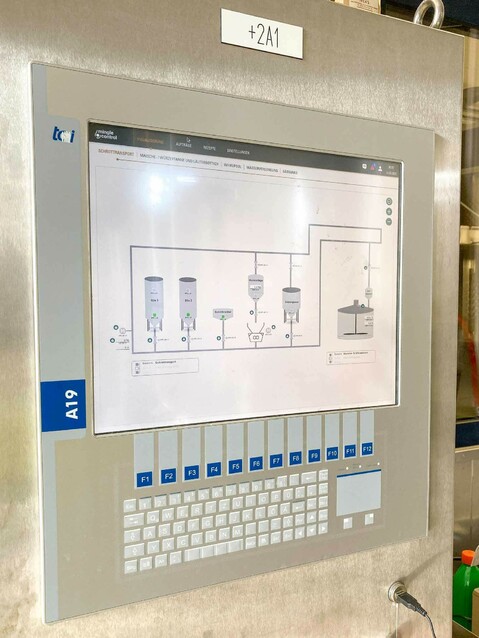

The operating system of the brewhouse control computer had become outdated. Since Microsoft no longer supported Windows XP from 2014, computers with this operating system are more susceptible to security risks and viruses. Furthermore, the existing S7-300 PLC control was also discontinued by the manufacturer. An update made sense here as well, so Robert Neumaier turned to us. The brewhouse from 2010 was to be taken to a new level with the help of minglecontrol.

The goal was to automate it anew, close existing security gaps, and thereby make the processes even more efficient.

Special features of the project

Robert Neumaier specifically wanted to simplify and improve the batch traceability of his products. For this purpose, the temperature profiles of the existing three fermentation tanks are now recorded in detail thanks to the newly installed S7-1500 PLC control. minglecontrol uses the data obtained to integrate it into the logging function. In this way, all values can be documented in a graphical visualisation in the corresponding brew log and appealingly presented.

Would you like to know what else sets minglecontrol apart? We provide you with numerous reasons why it is exactly the right process technology for your production!